What is LGSF

In the modern construction community, since the 1950s, there has been a need to increase the speed of building of structures. Classical construction technologies have been supplemented by the ability to use thin-walled profiles of various geometric shapes, produced by the method of continuous profiling of steel strips. Such groups of profiles formed the basis for the creation of a technology called LGSF (Light Gauge Framing System). Canada is considered to be the birthplace of this technology, but it has become

widespread and actively used in the Scandinavian countries and on the territory of modern Europe.

The technology has found its application in the construction industry for the building of both residential buildings with up to 5 floors and in industrial construction. The most popular architectural forms are superstructures on buildings with weak foundations for classical technologies, load-bearing structures for roofs and inter-floor ceilings, small architectural forms, and elements of ventilated facades. In addition, profiles are actively used in many other areas of life, such as the automotive and aircraft industries.

The basic principle of constructing structures based on LGSF technology is the calculation of the load-bearing capacity using the “end element method”. In the production of such elements, are used almost all grades of steel that have the ability to be turned by pressure. However, design rules clearly regulate the use of structural steel grades, for example S280-450GD with high-quality anti-corrosion coating 275–500 grams/m2. Such rules are not accidental. The use of thin-walled sheets from 0.7 mm to 4 mm necessarily increases the requirements for local stability and local deformations of nodal connections and directly used profiles.

Every year the construction industry takes on new challenges and rules regarding the responsibility of structures and their quality. The rules and regulations of thermal engineering, seismic engineering and fire resistance are observed and are evolving in LGSF technology.

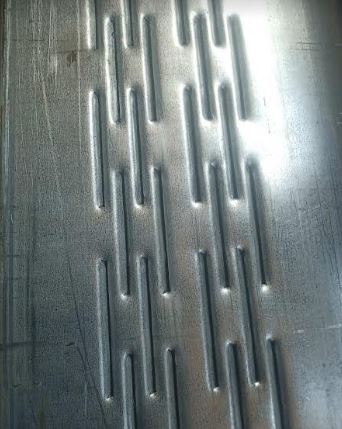

Even today, the fire resistance of structures is ensured by the structural protection of load-bearing elements; freezing of steel frames is solved by the production and use of profiles with special TERMO perforation. Minimization of freezing is ensured by the transition of linear to local from a stepwise principle.

Seismic stability is ensured by a dense lattice of finite elements, which in turn is adaptive to the placement of mineral insulation.

The architectural capabilities of LGSF have no restrictions. Elements of facades, complex roofs, cantilever terraces, balconies, extensions, attic floors – all of this is already used many times in construction today. The use of lightweight steel frames as enclosing structures of external walls in high-rise housing construction is one of the promising ways of development. The possibility of using a ready-made wall panel with a facade element in a multi-storey building significantly reduces the construction speed.

High-quality design of LGSF is impossible without the use of modern software calculation systems due to the peculiarities of calculations of thin-walled elements. In turn, a high-quality design stage minimizes costs in the production of structures and their construction. The design is standardized according to Eurocode 3. In Ukraine DSTU-N B V.2.6-87:2009.

Srco is one of the leading LGSF manufacturing, construction, and fabrication companies in Poland, Europe. Light Gauge Steel Framing (LGSF) technology is a modern frame technology of light gauge steel structures construction of cottages, warehouses, industrial premises, shopping malls, townhouses, and Small architectural forms.

SRCO is one of the leading companies in LGSF manufacturing in Europe.

LOCATION

Ukraine,

st. 14-ho Hrudnya 8

Cherkasy,

Cherkasy district

+38 063 700 12 49

Poland,

Katowice silesia

+48 88 08 47 265

e-mail: office@srco.pro

MORE